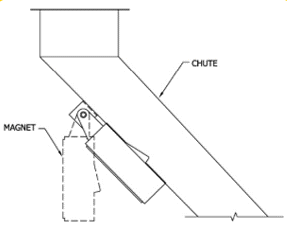

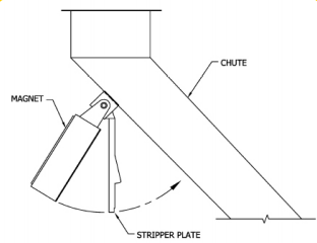

The IMT Magnetic Plate Separator (MPS) provides a dependable means of tramp metal extraction in chute applications.

Remove ferrous material in chutes with Magnetic Plate Separators

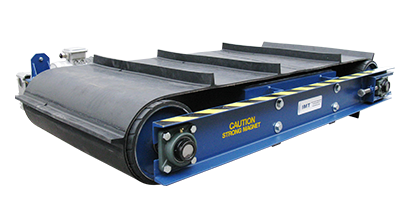

The permanent magnetic forces protect your capital equipment by providing continuous and effective removal of unwanted tramp metal. The Magnetic Plate Separator will increase uptime, reduce maintenance costs while providing a metal free product. Innovative Magnetic Technologies offers plate magnets in various sizes and configurations to meet your specific application; maximizing the separator’s performance.

MPS Series Magnetic Plate Separators

Magnetic Plate Separators are used to extract tramp metal from free-flowing products such as grains, pellets, powders, wood, and aggregate. These industrial strength magnets often employ super powerful rare earth magnets to ensure a clean end product. These magnets easily retrofit into your existing chutes and conveyors – or can be custom designed and built into a system that will work for your particular application. Our plate separators prolong the life of your existing equipment by reducing the wear and tear from errant metal.

Permanent Magnetic Power

- Power fluctuation or failures will not release captured tramp

- Guaranteed magnetic strength for the life of the application

- No power consumption

Simple Installation

- Permanent Magnetic Plate Separators are easily retrofitted into existing chute and hoppers

- Custom powerful rare earth models may be retrofitted to replace existing under performing magnets

- Manual and self-clean models available

- Available in a wide range of sizes and options

Magnetic Plate Separators are used in a wide variety of industries.

At Innovative Magnetic Technologies we believe in simple and painless solutions. Our team of experts will assess your needs and ensure you receive the right magnetic product for your application, and will custom build any of your infrastructure to meet your specific needs.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.