Magnetic Head Pulleys are used to continuously extract tramp metal from conveyor belt systems.

Magnetic Head Pulley

The Magnetic Pulley is an industrial strength magnet which provides a dependable means of tramp metal extraction on conveyor belt applications. The permanent magnetic forces protect your capital equipment, increase up time, reduce maintenance costs, and ensure highest product purity.

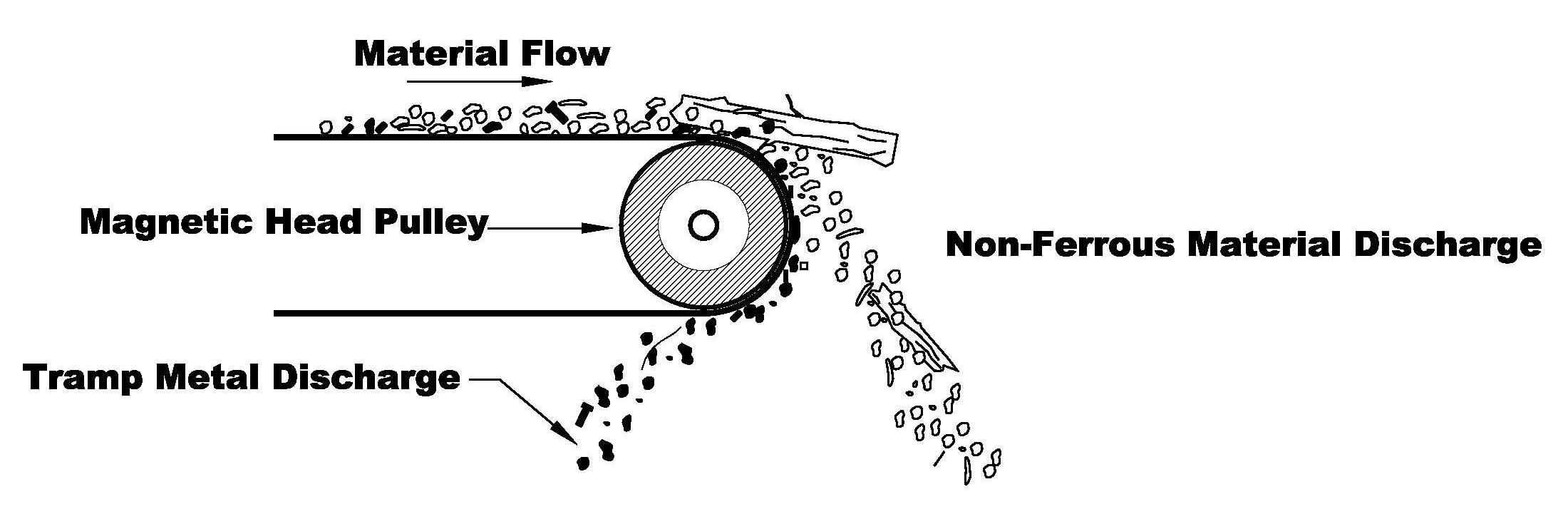

How a Magnetic Pulley works

A Head Pulley Magnet is a self cleaning magnet which removes foreign tramp metals from bulk materials on a belt conveyor. The magnetic field adheres ferrous contaminants to the belt as clean product passes over the head pulley. Tramp metals from the underflow can be safely captured in a bin to be discarded.

A magnetic take off rail conveys captured tramp metal further down the return side of the conveyor. The take off rail paired with the IMT Magnetic Head Pulley allows for a more convenient and smoother release of retained tramp metal reducing belt wear while discharges in a suitable location.

Magnetic Head Pulley Features

- Magnetic core available in Ceramic (Ferrite) and Rare Earth (Neodymium) configuration

- Size Ranges 10″ and up (custom sizes available)

- Ease of installation into existing systems

- Guaranteed magnetic strength for the life of the application

- No power consumption

Interested in a Pulley Magnet? Contact us at +1(250)491-5806 or via sales@imt-inc.com

Magnetic Pulleys are used in wide variety of industries.

These powerful magnets remove nails, metal wires, nuts & bolts, metal shavings, tools, and other ferrous contaminants in industries such as:

The professional separation fabricators at Innovative Magnetic Technologies will manufacture your Magnetic Head Pulleys to your required specifications. We design and build custom systems from conveyors to chutes and everything in between. Our experience with custom design and fit has earned us a niche in the manufacturing of magnetic separation equipment and products. IMT provides unsurpassed customer service and workmanship to every one of our clients.

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Innovative Magnetic technologies Inc. designed and manufactured Suspended Plate Magnets (SPM) are…

IMT designed and manufactured Cross belt and inline separators for facilities that have a high contamination…

Electromagnetic Separators are available in many configurations, sizes, and strengths to meet…

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.