Magnetic Separators for

VIBRA-SEP – Capture Tramp Metal before Metal Detectors in Vibratory Conveyors

IMT’s unique VIBRA-SEP magnetic plate design allows operations to easily retrofit a tramp metal separation solution without any modification to the existing conveying system.

The VIBRA-SEP is available for all vibratory conveyor widths, with 18″ and 24″ units in stock. Installation takes minutes, all hardware is provided and no welding is required.

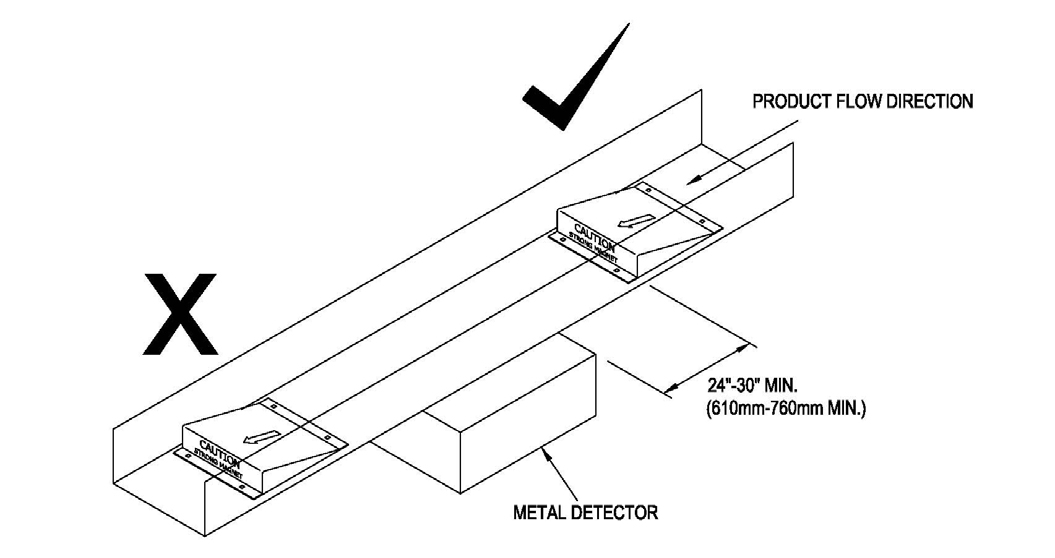

Installation Configuration

Installing the VIBRA-SEP in vibratory conveyors and feeders is an effective means of capturing tramp metal contaminants. Positioning this magnetic plate separator before metal detection systems reduces nuisance trips which create costly down time and labor costs associated with metal detection systems.

VIBRA-SEP – High Performance and Budget Friendly

- The VIBRA-SEP is a one component magnetic plate separator consisting of a large re-engineered, more powerful permanent magnetic core. The stainless-steel construction provides processing facilities with a separation system that will provide years of dependable maintenance free operation.

- In the production of wood chips, the Vibra-Sep is installed ahead of the metal detector. The Vibra-Sep removes tramp metal thereby reducing nuisance trips and increasing uptime. The Vibra-Sep also extracts smaller ferrous particles which the metal detector may not detect thus increasing chipper knife life (less pins and fines).

- Simple installation is accomplished in minutes by bolting the leading edge and trailing edge with included hardware.

- Removal of the captured tramp metal is done by simply sliding the captured contaminates off the face of the trailing edge.

- Increased uptime, reduce maintenance costs and a metal free product.

- Vibratory Magnetic Separators remove tramp metal from shaker and vibratory conveyor systems to increase product quality and protect processing equipment from damage. They increase productivity by cutting down on man hours, and are simple to operate and clean.

Vibratory Magnetic Separators are commonly used in industries such as:

- Mining

- Saw Mills

- Pulp Mills

- Food Services

- Animal Feed

This simple product is easy to install and is customizable to suit the needs of any application. We are application specialists in the separation metals industry, and as such, have the knowledge and experience to make your production line as efficient and productive as possible. Our professionals will assess your existing infrastructure and help develop and construct a unique system that will help to improve your output and your production.

How Products Like A Magna Wedge Protect Your Equipment

Unwanted ferrous metals are quite common in bulk products. To stop these errant pieces from getting into your equipment, consider the addition of a vibratory feeder magnet. A Magna Wedge (magnetic wedge) can help. A Magna Wedge and the more robust powerful Vibra-Sep™ are designed to attract and remove ferrous tramp metal from the product stream to ensure it doesn’t enter processing equipment.

Easily Add to Any Existing Setup

The Vibra-Sep™ quickly mounts into place on the equipment’s feeder trough and are both safe and effective for both gravity and vibratory feeders. Debris is held by the wedge as it passes.

Protect Your Equipment

Increase your equipment’s lifespan and decrease maintenance cost and expensive downtime. By removing debris, your equipment will be operating in optimal conditions for years to come. Our magnetic separators seamlessly attract and remove tramp metal from equipment. This removal prevents equipment damage and costly shutdowns.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

The VIBRA-SEP decreases nuisance metal detection tripping while reducing damage to expensive size reduction equipment.

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.