IMT offers custom designed and manufactured industrial magnetic separators and magnetic equipment suited to provide the most effective solutions for existing locations and structures. Our custom designed magnetic equipment not only provides maximum effectiveness but reduces installation costs.

Proven, Reliable, and Professional Experience

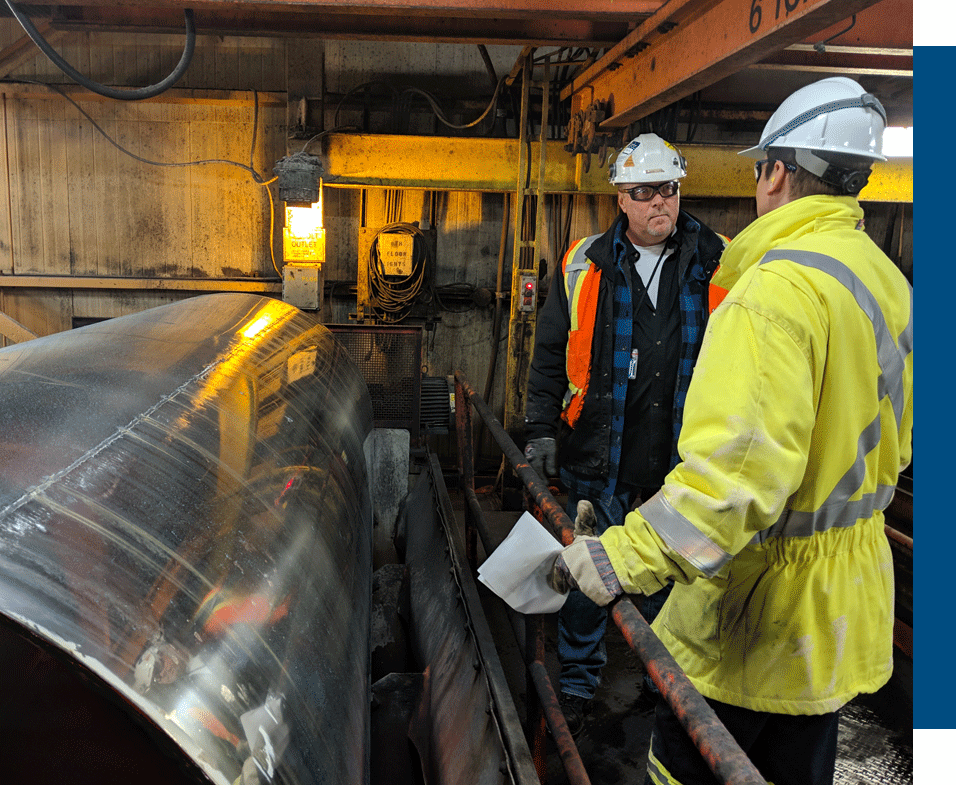

IMT provides on-site consultation to provide the most beneficial solution to your magnetic equipment requirements. We can evaluate your existing magnetic separation system and provide expert advice on how to maximize tramp metal recovery.

- Inspection of all Magnetic Separation Equipment

- Troubleshoot recovery challenges

- Gauss strength testing

- Inspection of installation configuration

- Provide optimization suggestions

Industrial Maintenance & Repair Services

IMT provides cost-effective maintenance and repair services, including wet drum separator rebuilds and conversion from left/right hand units to bi-directional. These services are an attractive alternative to purchasing new equipment. Contact us to learn more about our wide range of industrial maintenance and repair services.

Our wet drum separator refurbishment includes:

- Complete disassembly of separator

- Replace and or repair all bearings and seals

- Weld and machine drive stub shaft (inner seal surface)

- Remove and Reinstall magnetic core with rebuilt core assemblies

- Install a casing on the magnetic core to prevent any potential damage to drum from debris

- Sandblast and repaint inner steel yoke to prevent further corrosion

- Sandblast and paint inner bearing housings to prevent further corrosion

- Clean and coat aluminum endplates for enhanced corrosion and abrasion resistant

- Repair holes in stainless drum (if necessary)

- Remove and replace outer drum cover with Stainless Steel skin

- Clean and polish outer shaft stubs

- Reassemble drum, utilizing silicon and thread sealer when necessary

- Supply and install new fasteners

Fabrication Services

IMT provides on-site consultation to provide the most beneficial solution to your magnetic equipment requirements. We can evaluate your existing magnetic separation system and provide expert advice on how to maximize tramp metal recovery.

- AutoCAD design and 3-D modelling

- 5’ x 10’ Omax 60120 water jet machine center c/w multi axis cutting head and terrain follower

- In-house machine shop including lathes and milling machines

- Full Fabrication capabilities including mild steel, stainless and aluminum (MIG, TIG and Stick).

- Certified paint booth

- 5-ton gantry crane

- 2 Capacitor Discharge Machines

- Various steel processing equipment such as 80-ton press, drill presses, Oxy-Acetylene cutters, metal cutoff saws, band saws, sandblaster, steel belt sanders, plasma cutter

- Multi voltage motor test cabinet – 220v 3 phase, 480v 3 phase and 600v 3 phase

- 4 forklifts ranging from 5,000lb lift to 16,500lb

- Approximately 10,000 square foot production facility with 20,000 square feet of secure outdoor storage.

- Full ACAD and 3D modeling

Wet Drum Separator Refurbishment

IMT provides value added on-site consultation to provide the most beneficial solution to your magnetic equipment requirements. The IMT team can offer industrial facilities a turn-key installation option.

- Wet drum separator repair and overhaul

- Full visual assessment

- Drum shell inspection

- Core magnet replacement

- Bearing replacement

- Core Gauss testing

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.