Simple installation and maintenance for Suspended Permanent Magnets

Simplify the Installation and Maintenance of a Suspended Magnet

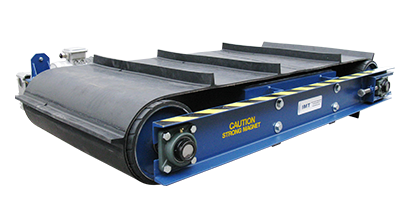

When you need to install a suspended magnet, IMT’s patented Actuated Maintenance System is the perfect solution. The AMS installs over the conveyor belt and allows operators to effortlessly remove captured tramp metal from the magnet’s surface. The frame eliminates the need for operations to come up with a costly suspension system for the separator while providing a safe and simple method of cleaning the captured tramp from the magnets surface.

The AMS Advantage

- Designed specifically for individual conveyors to ensure perfect fitment and ease of install

- Simplify removing tramp metal from the permanent magnet plate

- Increases safety for site operations while cleaning the magnet face

- Onboard 120V AGM battery good for 100+ actuations on a single charge

- Solar charging options available for remote operations

Introducing the AMS Suspended Magnet System

IMT’s patented (US Patent#10,112,201B2) Actuated Maintenance Stand allows operators to quickly, effortlessly, and safely remove captured tramp metal from the permanent magnetic separators surface.

The AMS Suspended Magnet Frame features:

- Full height adjustment

- Mounted winch

- Enclosed AGM battery

- Waterproof fully interactive on-board charger

- Lifting clevises

- Remote switch which can be used from either side of the conveyor

- Prewired and only requires a 120v plug in/hook up for charger

- Solar power option to maintain the battery charge

- Optional discharge capture tray available

The AMS Suspended Magnet Frame in Action

This video shows an installation in a Sawmill located in the Southern United States. The installation was completed in only 3 hours from the time the install team showed up onsite to the time they left.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.