Electromagnets are used in many heavy industries for separation of ferrous metal from bulk material processes.

Unlike a permanent magnet, these powerful separators use an electrical current to produce a strong and deep reaching magnetic field. This allows for peak capture performance in applications where there is a deep burden depth, high belt speed, entrapping material, and large tramp metal such as loader bucket teeth.

Typically suspended over a conveyor belt in either a cross-belt or inline configuration, electromagnetic separators pull tramp metal through the conveyed material and is removed from the process. This ensures a contaminant free product, but also protects conveyor belting, pumps, screens and other process equipment down the line.

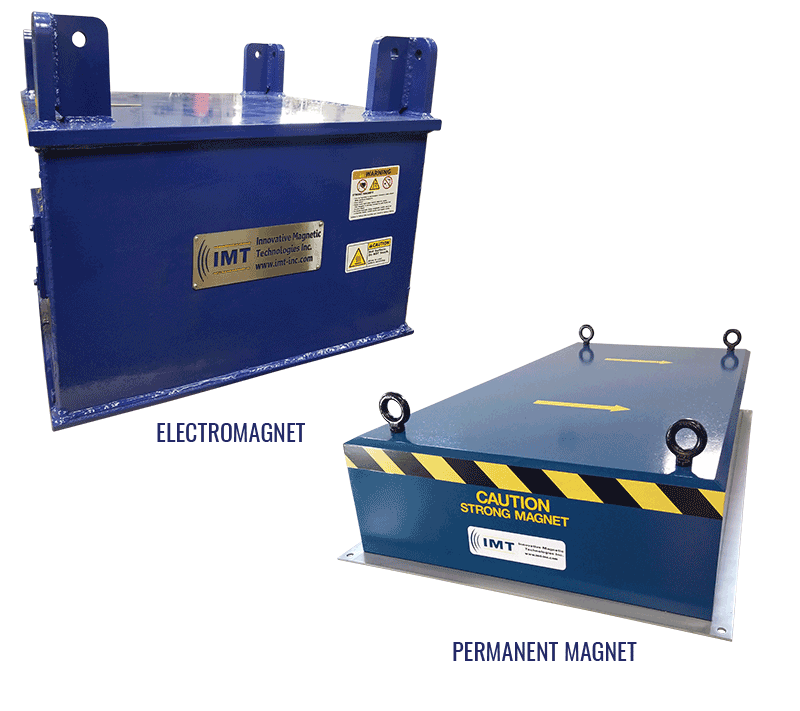

Industrial Electromagnets vs Permanent Magnets

There are several key differences between electromagnets and permanent magnets.

- Magnetic Field Reach Out: Electromagnets provide a greater reach out distance when compared to permanent magnets.

- Magnetism availability: Permanent magnets are always magnetized, while electromagnets can be turned off by stopping the electrical current.

- Control of ferrous material: Electromagnets have the benefit of being able to hold and release on demand, while permanent magnets cannot offer the same level of control.

Suspended electromagnetic separators bring strength, durability, and dependability to industrial producers with their capacity for power, control and adaptability. They are an excellent choice in defending against tramp metal in heavy industrial operations.

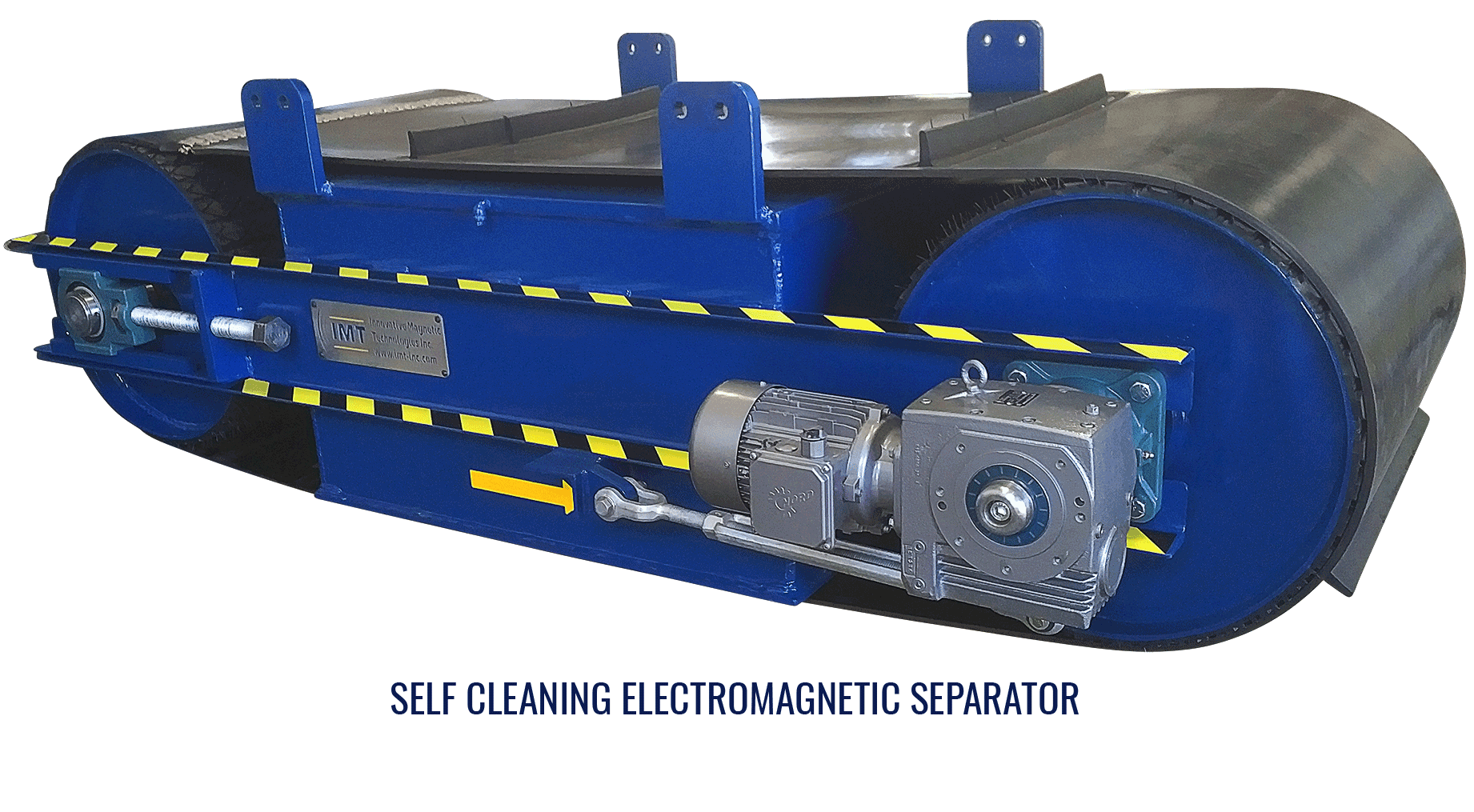

Self-Cleaning vs Manual Cleaning

Electromagnetic separators are available in either manual cleaning or self-cleaning models.

In order to clean the magnet face of a manual cleaning magnet, the magnet must be shut off which releases the captured tramp metal and subsequently falls from the magnet face. Typically, a trolley system is installed to move the magnet away from the conveyor so the reject ferrous material can fall directly into a bin or on the ground.

Self-cleaning electromagnetic separators feature a continuously rotating cleated belt around the unit. When ferrous tramp material is captured to the belt, the cleats swiftly move the tramp across the magnet face where it is discharged once it leaves the magnetic field. Self-cleaning electromagnets are by far the most desirable configuration in operations where frequent amounts of tramp metal as it does not interrupt the process.

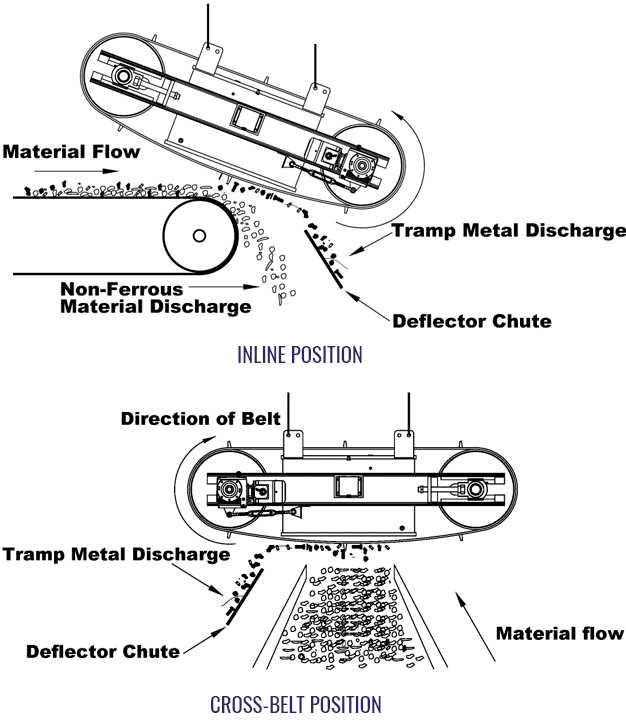

Self-Cleaning Positioning

Suspended electromagnets can be installed in two different positions, either cross-belt or inline. Choosing the optimal configuration depends on many factors and it is important to understand the benefits of each to ensure maximum tramp metal separation.

Installing a self-cleaning electromagnet in a cross belt configuration means the magnet is suspended perpendicular to the belt conveyor. Ferrous material is attracted by the strong magnetic field, pulled through the burden, and captured to the magnet face where it is discharged to a reject bin or chute off the side. Positioning the magnetic separator over the head pulley provides optimal recovery as the conveyed material is in free fall and tramp metal is freed from the burden in a kinetic state.

Inline positioning of a belt magnet means the unit is installed parallel to the conveyor and suspended over the head pulley. Ferrous material is extracted from the conveyed material as it passes over the head pulley, held to the rotating belt around the electromagnet and then discharged to a chute beyond the conveyor. Typically, a splitter plate is installed to segregate the desired product flow from the reject flow.

Electromagnetic separators are sturdy and can withstand many different environments. They are customizable and can be retrofitted into existing infrastructures. Well suited for large scale production, they are commonly used for the removal of unwanted metal in many different applications.

Use of Electromagnets Across Different Industries

- Mining: Removal of metal scraps, bucket teeth, rebar and other tramp metal from production to prevent damage to downstream process equipment such as conveyor belts, pumps, screens, and hydrocyclones.

- Aggregate: Extracting tramp metal such as rebar, metal scrap, and tools from conveyed crushed rock.

- Wood: Removing ferrous materials such as wire, tools, and metal scrap to protect chippers and hogs.

- Biomass: Ensuring metal free products such as wood pellets while protecting equipment from tramp metal.

- Recycling: Prevents metal contamination in final product and protects comminution equipment from damage.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

IMT designed and manufactured Cross belt and inline separators for facilities that have a high contamination…

Innovative Magnetic technologies Inc. designed and manufactured Suspended Plate Magnets (SPM) are…

Magnetic Head Pulleys provide a dependable means of tramp metal extraction on…

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.