Magnetic separators come in many forms that are suited for different applications, and most are customizable to accommodate existing infrastructure.

Magnetic separation is commonly used across numerous industries with the goal of extracting ferrous material from conveyed product. This material falls into one of two categories, tramp metal and ferromagnetic minerals for concentration/recovery.

Tramp metal is a ferrous metal contaminant such as tools, bolts, wire, and broken parts from upstream equipment. Tramp metal needs to be extracted during processing as a matter of safety, product quality, and protection of downstream equipment in production operations such as flour, grain, wood chips, recycling, and minerals.

The second category applies to the concentration and recovery of ferromagnetic minerals in mining industry. These minerals are predominantly magnetite, which is an iron oxide with the strongest naturally occurring magnetic properties on Earth. Magnetite is one of the most widely used raw materials in the production of iron, in which magnets are used to separate the magnetic mineral from gangue. In coal, potash, and diamond production, magnets are utilized to recover magnetite media which is used in dense media separation circuits.

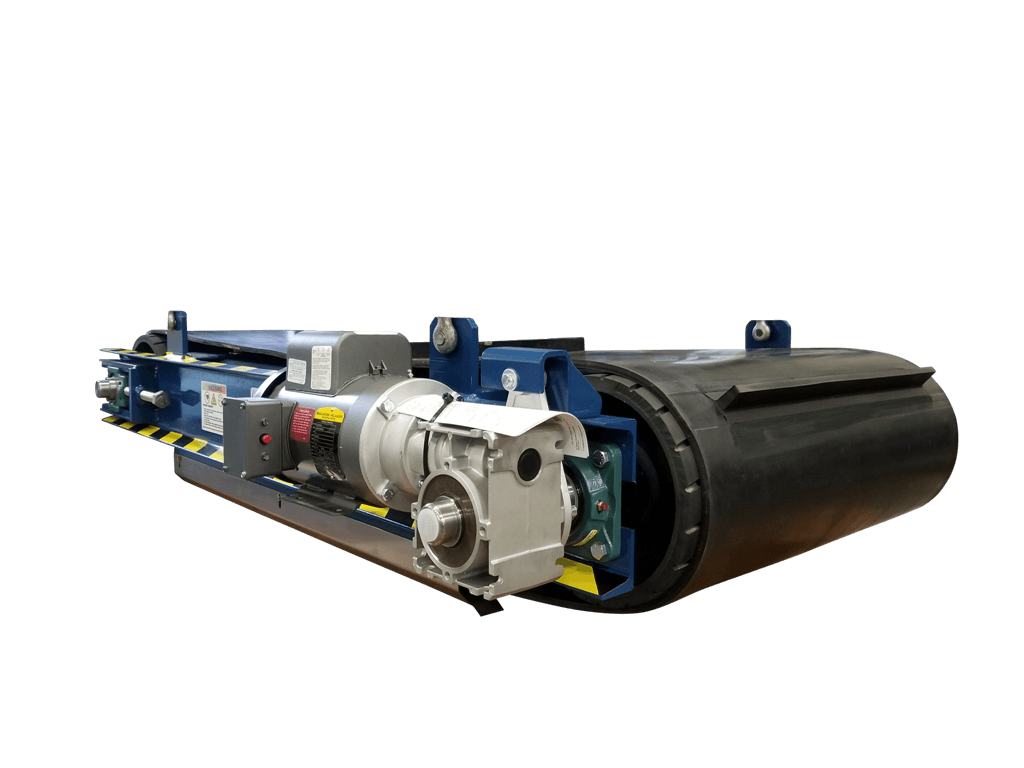

Drum Magnets

Magnetic Drum Separators operate by attracting ferrous material to a magnetic element enclosed within a rotating cylindrical stainless steel drum. These particles are cleared with every rotation of the drum and are moved into a separate output. Contaminants are safely removed from the production line while the continuous self-cleaning function clears debris from the drum.

To ensure optimal recovery, there are many factors to consider when sizing a drum magnet such as type of material being processed, volume per hour, particle size range, and size of ferrous material desired to be removed.

Type of Drum Magnets

- Enclosed Drum Magnets – IMT’s enclosed magnetic drum separators are perfect for vertical gravity fed chute applications for dry, free flowing material.

- Structural Drum Separators – IMT’s structural magnetic drum separators feature an infeed chute and splitter and are custom designed to be installed in large conveying systems for effective tramp metal removal.

- Standalone Drum Separators – Standalone magnetic drum separators are available in high-intensity rare earth (neodymium) and ceramic (ferrite) magnetic cores.

- Wet Drum Separators – Wet drum separators are commonly used in slurry applications for mining operations with heavy media circuits and iron ore concentration.

Advantages of Drum Magnets

- Self-cleaning

- Available in different sizes

- Accommodate high volumes

- Easy to operate

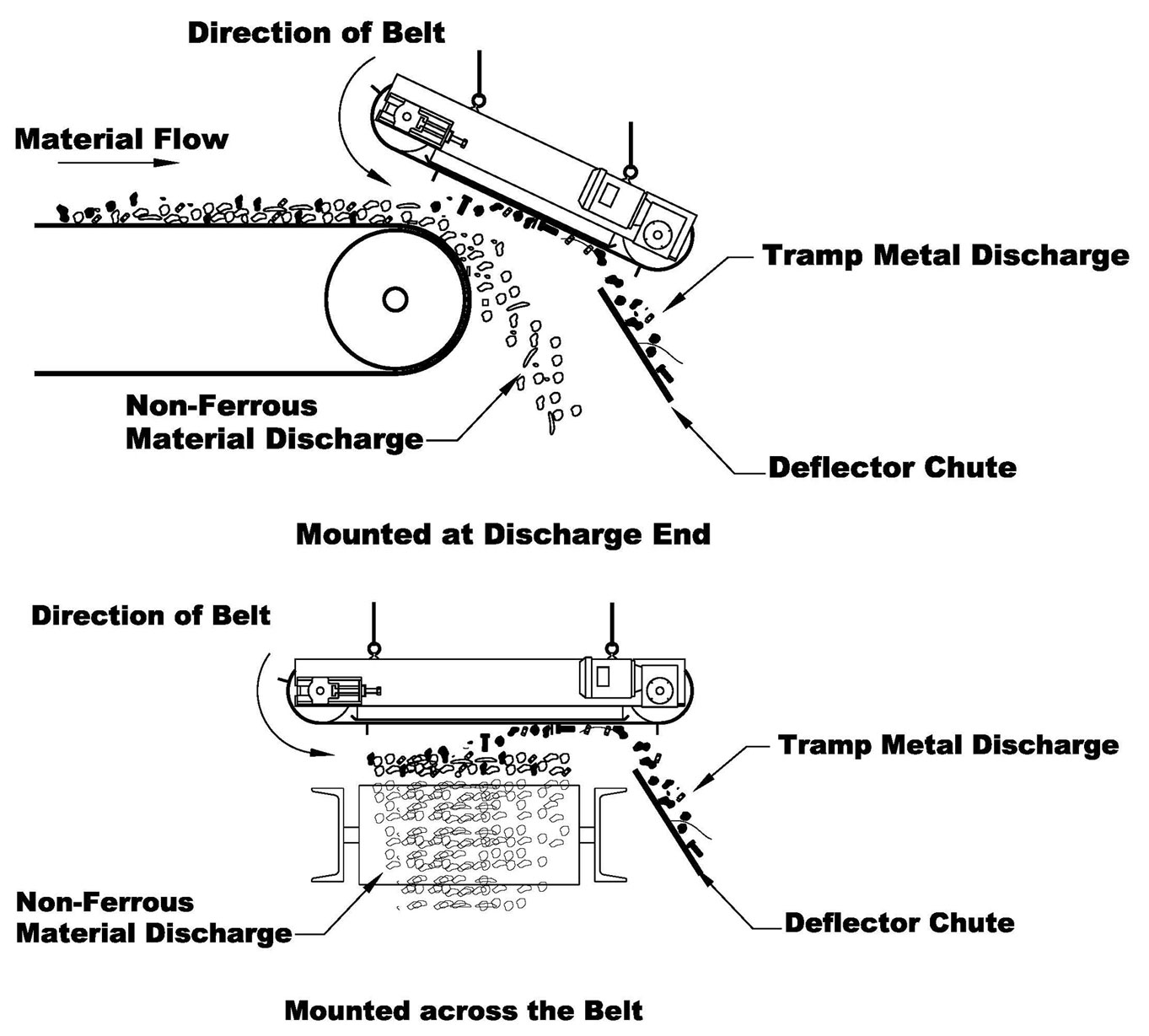

Magnetic Separators

Magnetic separators are valuable equipment used in many different applications to separate ferrous material from non-ferrous materials. This equipment uses rare earth or ceramic magnets to attract ferrous particles and extract them from output. They are optimum for large scale processing as they improve quality control and equipment reliability in manufacturing.

There are many types of magnetic separators including:

- Cross belt separators

- Magnetic plate separators

- Suspended plate magnets

- Vibratory conveyor magnetic separators

Permanent Magnetic separators can be used to extract tramp metal from consumer product, or to protect valuable equipment from damage during processing. An added benefit is that these permanent magnets will not lose power during an outage, so there is no risk of contamination in the event of power failure.

Electromagnetic Separators are used in high density, high burden depth, and high belt speed applications which require an extremely strong magnetic field. In order to discharge the captured tramp metal, simply turn the magnet off or use a self-cleaning belt magnet.

They are easily adaptable to existing infrastructure and can be customized to suit the needs and space constraints of customers across all industries.

Magnetic Separator and Drum Magnet Applications

Magnetic separators and drum magnets are employed in many different industries. Where there is a need for bulk separation of ferrous metals, this highly efficient equipment can increase uptime and improve product quality.

Biomass: In the production of wood pellets, magnetic separators protect equipment from tramp metal damage and produce a contaminant free product.

Bulk Handling: Ship loading and unloading facilities extract metal contaminants from consumer products such as grain and minerals.

Pulp and Paper: Produces a metal free product while protecting grinders and chippers from damage.

Wood Processing: Reduce metal detector tripping and reduce downtime by eliminating tramp metal damage to costly equipment.

Mining: Reclaim and concentrate ferromagnetic minerals in heavy media and iron ore production.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

IMT designed and manufactured Cross belt and inline separators for facilities that have a high contamination…

Innovative Magnetic technologies Inc. designed and manufactured Suspended Plate Magnets (SPM) are…

Magnetic Head Pulleys provide a dependable means of tramp metal extraction on…

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.