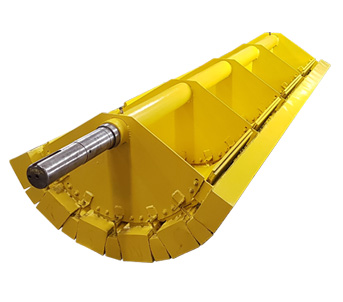

Wet Drum Separator Rebuild Program

IMT provides cost-effective Wet Drum Separator rebuilds and optimization services for a wide scope of manufacturers units. Our rebuilt wet drum magnets are utilized in Heavy Media and Concentrator circuits by many coal, potash, and iron ore mines in Canada and all across North America. IMT’s wet drum core design offers optimal magnetic field projection and strength resulting in maximum recovery and concentration performance.

Conversion from Left and Right Hand to Bi-Directional Units

Our services can convert uni-directional (left and right hand) wet drum separators to bi-directional units. This conversion alleviates the need for operations to stock two different units for their plant and provides a standard drum configuration for use in multiple locations reducing inventory requirements.

Our rebuild services are an attractive alternative to purchasing a new unit, call us at 1(888) 991-5806 or email sales@imt-inc.com to discuss how we can support your operation.

Wet Drum Separator Extensive Rebuild Program:

- Complete disassembly of separator

- Replace and or repair all bearings and seals

- Weld and machine drive stub shaft (inner seal surface)

- Remove and Reinstall magnetic core with rebuilt core assemblies

- Install a casing on the magnetic core to prevent any potential damage to drum from debris

- Sandblast and repaint inner steel yoke to prevent further corrosion

- Sandblast and paint inner bearing housings to prevent further corrosion

- Clean and coat aluminum endplates for enhanced corrosion and abrasion resistant

- Repair holes in stainless drum (if necessary)

- Remove and replace outer drum cover with Stainless Steel skin

- Clean and polish outer shaft stubs

- Reassemble drum, utilizing silicon and thread sealer when necessary

- Supply and install new fasteners

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.